Square Hollow Section,Square steel pipes

Home >

-

API steel pipe

- API steel pipe

- API steel casing pipe

- Casing and Tubing

- API drill pipe

- API5L steel pipe

- Oil pipeline

-

Carbon steel pipe

- Carbon steel pipe

- Welded steel Pipe

- seamless carbon steel pipe

- Petroleum Casing Pipe

-

Alloy steel pipe

- astm a 335 gr p22

- alloy steel pipe l555

- 25crmo4 alloy steel pipe

- alloy pipe a335 p11

- interpret seamless steel pipe

- Water pipeline - Handling and

- Applications of welded pipe pil

- welded steel pipes and Seamless

- ASTM A 106 Seamless Pipe

- Carbon dioxide resistant oil ca

- seamless steel pipe On-line col

- EN 10305-1 / DIN 2391 cold draw

- EN 10255 Standard Pipe,replaces

- API 5L A53 / A106 Grade B, Seam

One of the Top 500 enterprises in China foreign trade

QCCO was approved as a member of “China Association for Contracting Projects Abroad “and granted a membership certificate on Sep 28,2005; “Credibility Rating AAA certificate in Foreign Trade” was granted to QCCO by China Shippers’ Association

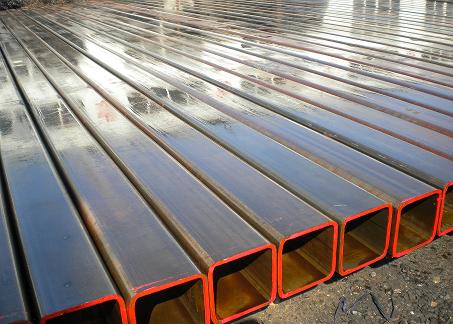

Square Hollow Section,Square steel pipes

Square Steel Tubes

Application:

It is widely used in building, machine, chemical equipment, automobile industrial, container, it is also applied to agriculture and mine machine.

We manufacture a wide range of square hollow section which finds usage in many industries for various applications. We are manufacturing these square hollow sections at our state-of-the-art facility and in compliance with international quality standards. Our range of products is meticulously tested on various parameters such as tensile strength, flattening, bending, drift expansion, etc. We believe in delivering the highest quality products to our clients and within stipulated time frame.

.

.

Square Hollow Section,Square steel pipes

Standard:

ASTM A500, GB6728

Steel grade:

ASTM A500: A, B, C

GB6728:Q195,Q215,Q235,Q345

Standard: ASTM A500

Chemical Composition(%)

|

Chemical Requirement |

||||

|

|

Composition % |

|||

|

|

Grade A |

Grade B |

||

|

|

Heat |

Product |

Heat |

Product |

|

Element |

analysis |

analysis |

analysis |

analysis |

|

Carbon max |

0.26 |

0.3 |

0.22 |

0.26 |

|

Manganese max |

… |

… |

1.4 |

1.45 |

|

Phosphorus, max |

0.035 |

0.045 |

0.03 |

0.04 |

|

Sulfur max |

0.035 |

0.045 |

0.02 |

0.03 |

|

Copper, when copper steel is specified, min |

0.20 |

0.18 |

0.2 |

0.18 |

|

Where an ellipsis (...)appears in this table, there is no requirement |

||||

|

For each reduction of 0.01 percentage point below the specified maximum for carton, |

||||

Mechanical Properties

|

Tensile Requirement |

||

|

|

Grade A |

Grade B |

|

Tensile strength, min, psi (Mpa) |

48000 (400) |

70000 (483) |

|

Yield strength, min, psi (Mpa) |

36000 (250) |

50000 (345) |

|

Elongation in 2 in. (50.8mm), min, % |

23 |

23 |

GB6728:

|

SteelGrade |

CHEMICAL COMPOSITION |

MECHANICAL PROPERTIES |

||||||

|

|

C (%) |

Si (%) |

Mn (%) |

P(%)

Max |

S (%)

Max |

YS(Mpa)

Min |

TS(Mpa)

Min |

El (%)

Min |

|

Q195 |

0.06-0.012 |

0.3 |

0.25-0.5 |

0.45 |

0.5 |

195 |

315 |

22 |

|

Q215 |

0.09-0.15 |

0.3 |

0.25-0.55 |

0.45 |

0.5 |

215 |

335 |

22 |

|

Q235 |

0.12-0.22 |

0.3 |

0.3-0.7 |

0.45 |

0.45 |

235 |

375 |

20 |

|

Q345 |

0.20 |

0.55 |

1.0-1.6 |

0.45 |

0.45 |

345 |

510 |

21 |