-

API steel pipe

- API steel pipe

- API steel casing pipe

- Casing and Tubing

- API drill pipe

- API5L steel pipe

- Oil pipeline

-

Carbon steel pipe

- Carbon steel pipe

- Welded steel Pipe

- seamless carbon steel pipe

- Petroleum Casing Pipe

-

Alloy steel pipe

- astm a 335 gr p22

- alloy steel pipe l555

- 25crmo4 alloy steel pipe

- alloy pipe a335 p11

One of the Top 500 enterprises in China foreign trade

TPCOINTL was approved as a member of “China Association for Contracting Projects Abroad “and granted a membership certificate on Sep 28,2005; “Credibility Rating AAA certificate in Foreign Trade” was granted to TPCOINTL by China Shippers’ Association

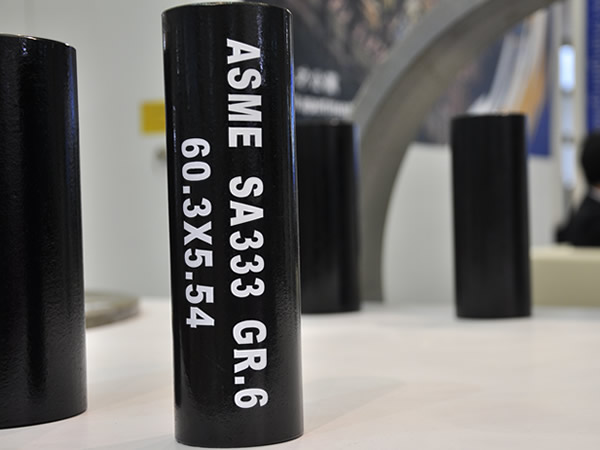

A333 GR.3,GR.6,GR.8 Pipe

ASTM A333 Seamless Pipe for Low-Temperature Service

1).Standard Executived: ASTM A333,ASTM A334

2).Materials: ASTM A333 Gr.1,Gr.3,Gr.6,Gr.7,Gr.8,Gr.9, Gr.10

3).Outside diameter:from 1/4" to 28"(13.7 mm to 711.2 mm)

4).Wall Thickness:2mm-100mm

Schedule: SCH40, STD, SCH80, XS, SCH160, XXS etc.

5).Length:4m-12.8m, customers' requirements

6).Ends:Plain ends or bevel ends

7).Coating for protection:can be required according to

customers'requirements

8).Other Materials: ASTM A334 Gr.1,Gr.3,Gr.6,Gr.7,Gr.8,Gr.9,Gr.11

ASTM A333 Standard covers seamless and welded steel pipe for low temperature service. The Grade 6 steel involved is similar to AISI 4032 low alloy steel. ASTM A333 Grade 6 pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

A333 Steel Pipe Material & Manufacture:

ASTM A333 Pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

Chemical Requirements

| Data | Composition, % | ||

| Element | Grade 1 | Grade 3 | Grade 6 |

| Carbon, max | 0.30 | 0.19 | 0.30 |

| Manganese | 0.40 – 1.06 | 0.31 – 0.64 | 0.29 – 1.06 |

| Phosphorous, max | 0.025 | 0.025 | 0.025 |

| Sulfur, max | 0.025 | 0.025 | 0.025 |

| Silicon | 0.18 -0.37 | 0.10 min | |

| Nickel | 3.18 – 3.82 | ||

For each reduction of 0.01% carbon below 0.30%, an increase of 0.05% manganese above 1.06% would be permitted to a maximum of 1.35% manganese.

When Grade 6 is ordered under this specification, supplying an alloy grade that specifically requires the addition of any element other than those listed for the ordered grade is not permitted. However, the addition of elements required for the deoxidation of the steel is permitted.

TENSILE REQUIREMENTS

The material shall conform to the requirements as proscribed:

| A333 Gr.1 pipe | A333 Grade.3 pipe | A333 Gr.6 pipe | |||||

| psi | MPa | psi | MPa | psi | MPa | ||

| Tensile Strength, min | 55,000 | 380 | 65,000 | 450 | 60,000 | 415 | |

| Yield Strength, min | 30,000 | 205 | 35,000 | 240 | 35,000 | 240 | |

| Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | ||

| Elongation in 2 in. or 50 mm, (or 4D), min, %: | |||||||

| Basic minimum elongation for walls 5/16 in.[8 mm] and over in thickness, strip tests,and for all small sizes tested in full section | 35 | 35 | 30 | 20 | 30 | 16.5 | |

|

When the standard round 2-in. or 50-mm gagelength or proportionally smaller size test specimen with the gage length equal to 4D (4 times the diameter) is used |

28 | 20 | 22 | 14 | 22 | 12 | |

|

For strip tests, a deduction for each 1/32in. [0.8 mm]decrease in wall thickness below 5/16 in. [8 mm] from the basic minimum elongation of the following percentage |

1.75 | 1.25 | 1.50 | 1.00 | 1.50 | 1.00 | |

| Elongation in 2 in. or 50 mm, min, %: | |||||||