API 5L line pipe seamless in various grades and sizes. Grades

Home >

-

API steel pipe

- API steel pipe

- API steel casing pipe

- Casing and Tubing

- API drill pipe

- API5L steel pipe

- Oil pipeline

-

Carbon steel pipe

- Carbon steel pipe

- Welded steel Pipe

- seamless carbon steel pipe

- Petroleum Casing Pipe

-

Alloy steel pipe

- astm a 335 gr p22

- alloy steel pipe l555

- 25crmo4 alloy steel pipe

- alloy pipe a335 p11

- interpret seamless steel pipe

- Water pipeline - Handling and

- Applications of welded pipe pil

- welded steel pipes and Seamless

- ASTM A 106 Seamless Pipe

- Carbon dioxide resistant oil ca

- seamless steel pipe On-line col

- EN 10305-1 / DIN 2391 cold draw

- EN 10255 Standard Pipe,replaces

- API 5L A53 / A106 Grade B, Seam

One of the Top 500 enterprises in China foreign trade

QCCO was approved as a member of “China Association for Contracting Projects Abroad “and granted a membership certificate on Sep 28,2005; “Credibility Rating AAA certificate in Foreign Trade” was granted to QCCO by China Shippers’ Association

API 5L line pipe seamless in various grades and sizes. Grades

Octal offers API 5L seamless line pipe from API 5L Gr B to X80, product specification level PSL1 and PSL2. Onshore/Offshore and sour services (H2S corrosive environment NACE pipe). Including manufactured in hot rolled seamless and cold drawn (rolled) seamless pipes. Largest diameters up to 40 inch.

API 5L seamless pipe supply range

Standard: API SPEC 5L (Latest edition)

Grades: B, X42, X52, X56, X60, X65, X70 and S (S for sour service, for example X70QS)

Steel Pipe Dimensions OD: 1/2” to 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inch, 18 inch, 20 inch, 24 inch, 26 inch to 40 inch.

Pipe Weight Schedule Thickness: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

Ends Type: Beveled ends, Plain ends

Length Range: 20 FT (6 meter), 40FT (12 meter)or customized

Protection Caps in plastic or iron

Surface: Natural, Varnished, Black painting, FBE and 3PE, Cladding and Lined etc

CRA Clad and lined pipe available (Carbon steel + cladding or lined alloy steel material)

Chemical Composition

Chemical composition for PSL 1 pipe with t ≤ 25.0 mm (0.984 in)

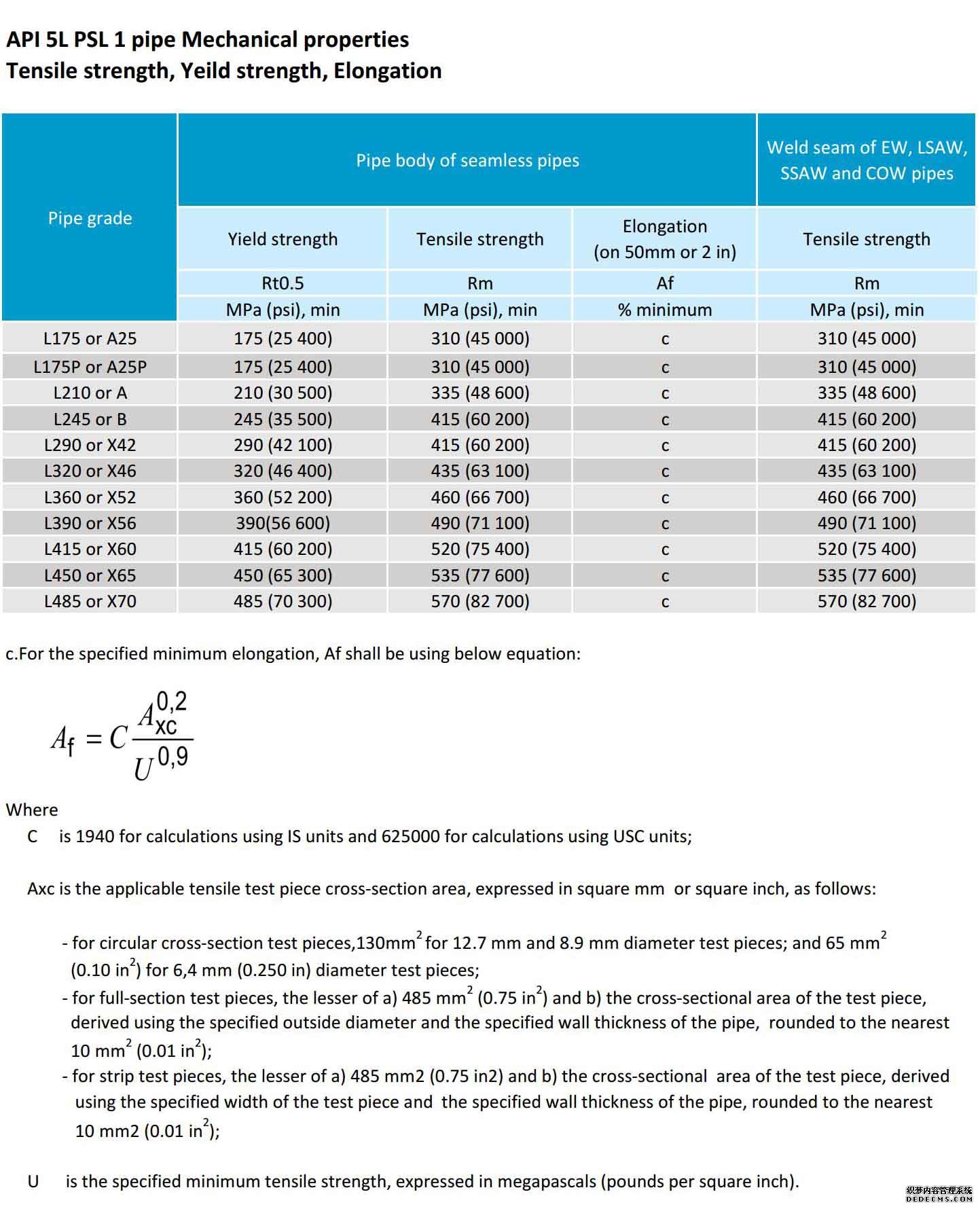

API 5L mechanical properties

Yield Strength and Tensile Strength for API 5L pipe for PSL2 pipes please view here

Dimensions tolerance for API 5L seamless pipe

a. For outer diameters less than 2 3/8 in (60.3 mm), pipe body diameter tolerance +/-0.5 mm. Pipe end +/- 0.5 mm; Out of Roundness tolerance for pipe body is 0.9 mm (0.036 in), pipe end 0.6 mm (0.024 mm).

b. For OD equal or above 2 3/8 in (60.3) to 24 in (610 mm), (diameter tolerance) for pipe body is +/- 0.0075D, pipe end +/- 0.005D but max to +/- 1.6 mm (0.063mm); Roundness tolerance for pipe body ≤ 0.015D, pipe end ≤ 0.01D.

(In case agreed with manufacturer and client, more strictly tolerances could be applied)

c. For wall thickness

Below than 4 mm (0.0157 in), tolerance +0.6 (0.024 mm), -0.5 mm (0.020 in);

For API 5L seamless line pipe thickness in 4 mm to 10 mm (0.394 in), +0.150t, -0.125t;

For API seamless pipe thickness 10 mm to 25mm (0.984 in), +/-0.125t;

Wall thickness ≥ 25 mm, +3.7mm or +0.1t (if larger) and -3.0 mm (0.120 in) or -0.1t (if larger).

t for thickness;

d. For straightness, max for full length, tolerance maximum 0.15% of length.

e. Straightness, max deviation for pipe end, shall be ≤ 0.3 mm /m.

f. Length +/- 200 mm for general, +/- 25.4 mm for special.

Seamless steel pipe manufacturing types

API 5L Seamless steel pipe production methods can be divided into: Hot-rolled seamless pipe, Cold drawn (rolled) pipe and tube, Thermal expansion pipe, Cold spinning tube and Squeeze tubes.

Formation – Seamless steel pipes are made from a round steel billet while welded pies are made from a strip which is rolled and welded. The formation process of seamless pipes involves forging, perforation, rolling, and shaping all at a time. The defects in the steel can be easily eliminated during the rolling process. On the other hand, the formation process of seamed or welded pipes involves bending plates and welding in desired shapes. The process of making welded pipes is less expensive, and hence, the prices are lower. But in terms of performance, seamless ones are way ahead.

Hot Rolled Seamless steel pipe manufacturing process

Hot Rolling Seamless Steel Line Pipe Manufacturing / Production processes

Rolled Round Billets – Examination – Cut Off – Heating – Piercing – Elongation – Slight Tension Reducing – Straightening – Corp End Cutting Off – Visual Inspection – NDT – Hydrostatic Test – Ends Procession – Product Inspection – Painting and Marking – Packing – Warehousing

Cold Drawn (Rolled) seamless line pipe manufacturing process

Mother pipe (Normally for hot rolled pipe) – Inspection – Annealing – Ends Treatment (Hitting and Drilling hole) – Pickling – Grinding – Phosphorization (Annoit) – Cold Drawn (Rolled) – Degreasing and Cleaning – Heat treatment (Solution treatment) – Straightening – Hydrostatic test – Painting and Marking – Warehousing

Our advantages

Top seamless steel pipe manufacturers in China, with high quality and competitive prices.

Further more, we offer:

a. Common sizes in stock.

b. Small quantity with different sizes.

c. Customized Length.

d. NACE MR 0175 pipe material stock available.

e. Fast delivery.

f. Big diameters seamless steel pipe. (Original seamless pipe in 20” 508 mm OD) Hot expanded to diameter up to 40 in, 1016 mm.

g. Material guaranteed high quality with full traceability.

Octal steel is one of the top steel pipe supplier in China, and we are popular for our high-quality and reasonable pricing. You will get all the common sizes of seamless steel pipes, and you can even order customized sizes. The delivery is fast, and the material used for manufacturing the pipes is of best quality.

API 5L Seamless Line Pipe Applications

For Petroleum and natural gas industries, pipeline transportation systems. Transmission of petroleum and natural gas.

API 5L Pipe Specification

上一篇:Applications of welded pipe piles and Testing and Materials

下一篇:Construction Technology of steel pipe for communication tower