Seamless Pipe for Fluid Transport

Home >

-

API steel pipe

- API steel pipe

- API steel casing pipe

- Casing and Tubing

- API drill pipe

- API5L steel pipe

- Oil pipeline

-

Carbon steel pipe

- Carbon steel pipe

- Welded steel Pipe

- seamless carbon steel pipe

- Petroleum Casing Pipe

-

Alloy steel pipe

- astm a 335 gr p22

- alloy steel pipe l555

- 25crmo4 alloy steel pipe

- alloy pipe a335 p11

- interpret seamless steel pipe

- Water pipeline - Handling and

- Applications of welded pipe pil

- welded steel pipes and Seamless

- ASTM A 106 Seamless Pipe

- Carbon dioxide resistant oil ca

- seamless steel pipe On-line col

- EN 10305-1 / DIN 2391 cold draw

- EN 10255 Standard Pipe,replaces

- API 5L A53 / A106 Grade B, Seam

One of the Top 500 enterprises in China foreign trade

QCCO was approved as a member of “China Association for Contracting Projects Abroad “and granted a membership certificate on Sep 28,2005; “Credibility Rating AAA certificate in Foreign Trade” was granted to QCCO by China Shippers’ Association

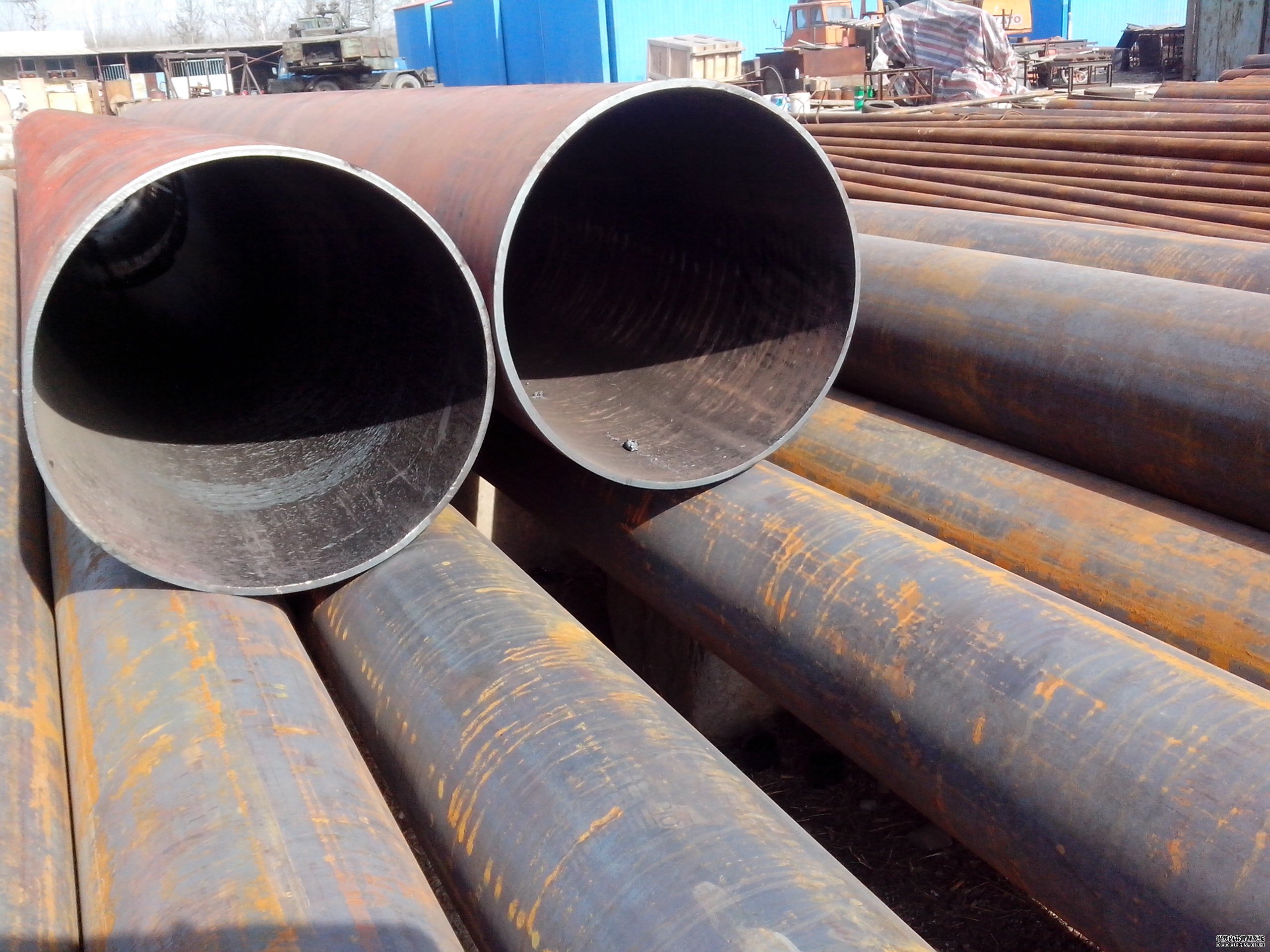

Seamless Pipe for Fluid Transport

Seamless Steel Pipe for Fluid Transportation

● National Standard: GB/T8163-2008

● Usage: used to transport fluids such as water, oil, and gas

● Main grade steel grades: 10 #, 20 #, Q345 (after consultation, other special grades of steel pipe can also be supplied. For example, Q295, Q390, Q420, Q460 quality grade is A, B, C, D)

● Chemical composition, machinery performance:

|

standard |

Steel grade | chemical composition(%) | ||||||

| C | Mn | Si | Cr | Ni | Cu | PS | ||

| GB/T8163 | 10# | 0.07 to 0.13 | 0.35 to 0.65 | 0.17 to 0.37 | ≤ 0.15 | ≤ 0.30 | ≤ 0.25 | ≤ 0.030 |

| 20# | 0.17 to 0.23 | 0.35 to 0.65 | 0.17 to 0.37 | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 | ≤ 0.030 | |

| Q345 | 0.12 to 0.20 | 1.20 to 1.60 | 0.20 to 0.55 | ≤ 0.030 | ||||

| Mechanical behavior | Tensile strength (MPa) | Yield strength (MPa) | Elongation(%) | |||||

| 10 | 335-475 | ≥ 205 | ≥ 24 | |||||

| 20 | 410 to 550 | ≥ 245 | ≥ 20 | |||||

| Q345 | 490~665 | ≥ 325 | ≥ 21 | |||||

● Dimensional tolerance:

|

Steel pipe type |

Steel tube size mm |

Allowable deviation | ||

| Ordinary level | advanced | |||

| Hot-rolled (extruded, expanded) tube | Outer diameter D | All | ±1%D (minimum ±0.50) | - |

| Wall thickness S | All |

+15%S (minimum +0.45) -12.5%S (minimum -0.40) |

- | |

| Cold drawn (rolled) tube | Outer diameter D | 6~10 | ±1%D or ±0.20 | ±0.15 |

| >10~30 | ±0.30 | ±0.20 | ||

| >30~50 | ±0.45 | ±0.30 | ||

| >50 | ±1% | ±0.8% | ||

| Wall thickness S | ≤1 | ±0.15 | ±0.12 | |

| >1~3 |

+15% -10% |

+12.5% -10% |

||

| >3 |

+12.5% -10% |

±10% | ||

|

*Note: The wall thickness tolerance is + 18%S for thermal expansion tubes with an outside diameter of not less than 351mm. |

||||