Classification of SA210C steel pipes and their advantages and

According to the current domestic production of SA210C steel pipe

Can be roughly divided into: hot-rolled seamless steel pipe, cold-rolled seamless steel pipe and precision seamless steel pipe. Overall: the advantages of seamless steel pipe are high pressure resistance, good toughness, long pipe section and few interfaces. The disadvantage is that the price is high, corrosion is easy, and the service life is short. Let us give you a detailed introduction below.

Advantages and disadvantages of a hot rolled SA210C steel pipe

Advantages: It can damage the cast structure of the ingot, refine the grain of the steel, and eliminate the defects of the microstructure, so that the steel structure is compacted and the mechanical properties are improved. This improvement is mainly reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent; bubbles, cracks and looseness formed during casting can also be welded under high temperature and pressure.

Disadvantages: 1. After hot rolling, non-metallic inclusions (mainly sulfides and oxides, as well as silicates) inside the steel are pressed into thin sheets, and delamination (sandwich) occurs. The delamination greatly deteriorates the tensile properties of the steel in the thickness direction, and it is possible to cause interlayer tearing when the weld is shrunk. The local strain induced by weld shrinkage often reaches several times the yield point strain and is much larger than the strain caused by the load.

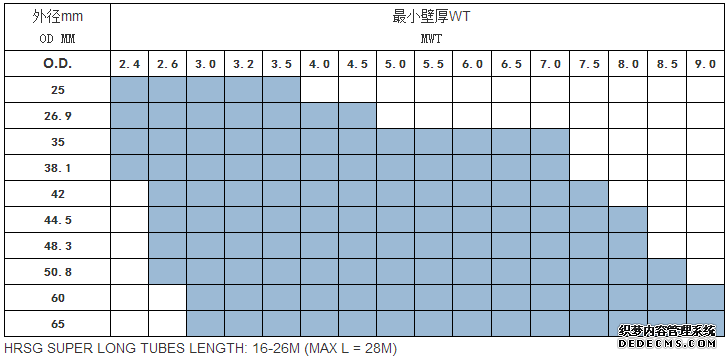

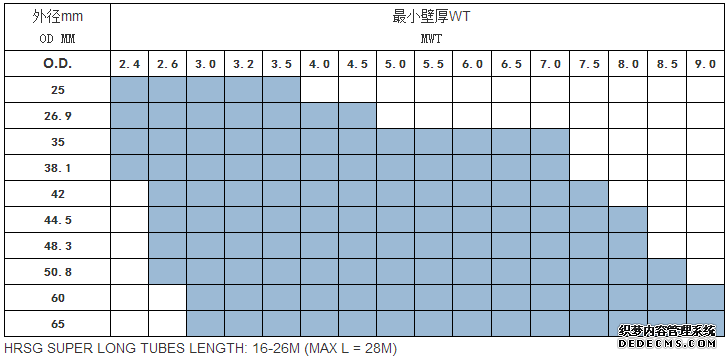

Product Size:26~65 mm(OD)*2.4~7mm(WT)*12~28m

Features Description :

In combined cycle, wast heat of tubine will be recycled by HRSC and generates steam to generate electricity . HRSG super long tubes are main components of HRSG. Our product had cover various sizes scope .We have many certificates and export tomore than 10 years .

Standard (part):

GB 5130-2008 Seamless steel tube for high pressure boiler

ASME SA210 Seamless medium carbon steel tube for high pressure boiler and superheater

ASME SA192 Seamless carbon tube for high pressure

ASME SA213 sEAMLESS Ferritic and Austenitic Alloy steel boiler ,super heater,and Heat exchanger Tubes EN 10216-2 Seamless Steel Tubes Technical Conditions for Pressure Usage

Main steel grades of HRSG super long tube

SA210A1 . SA210C . SA192 . SA213-T11. SA213-T22 . SA213-T91. SA213-T92. 20G. 15CRMOG. 12CRMOVG. P335GH.13CRMO4-5 ECT .

HRSG Size scope:26~65 mm(OD)*2.4~7mm(WT)*12~28m

2. Residual stress caused by uneven cooling. The residual stress is the internal self-phase equilibrium stress without external force. The hot-rolled steel of various sections has such residual stress. The larger the section size of the general steel, the larger the residual stress. Although the residual stress is self-phase-balanced, it still has some influence on the performance of steel members under external force. Such as deformation, stability, fatigue and other aspects may have adverse effects.

Advantages and disadvantages of cold rolled SA210C steel pipe

Cold rolling refers to the processing of steel sheets or steel strips into various types of steel at room temperature by cold drawing, cold bending, cold drawing and other cold working.

Advantages: fast forming speed, high output, and no damage to the coating, can be made into a variety of cross-section forms to meet the needs of the use conditions; cold rolling can make the steel produce a large plastic deformation, thereby increasing the yield of the steel point.

Disadvantages: 1. Although there is no hot plastic compression in the forming process, there is still residual stress in the section, which will inevitably affect the overall and local buckling characteristics of the steel;

2. The cold-rolled steel profile is generally an open section, so that the free torsional stiffness of the section is low. It is easy to twist when being bent, and it is prone to bending and torsion buckling when pressed, and the torsion resistance is poor;

3. The cold-rolled steel has a small wall thickness and is not thickened at the corners where the plates are joined. The ability to withstand localized concentrated loads is weak.

Advantages and disadvantages of three precision seamless steel tubes

Advantages: The outer diameter and wall thickness of the precision seamless steel pipe are relatively standard, and the precision seamless tube is bright. There is no oxide layer on the inner and outer walls, high pressure and no leakage, high precision, good surface finish, no cold deformation, no cracks, no cracks. Precision seamless pipe is suitable for demanding hydraulic system piping, automobile manufacturing piping, military, engineering machinery, railway locomotive, aerospace, marine, injection molding machine, die casting machine, machine tool, diesel engine, petrochemical, power station, boiler equipment, etc. industry.

Disadvantages: Long production cycle, low output and high cost.

The main difference between four hot rolling and cold rolling

1. Cold-rolled steel allows partial buckling of the section, so that the bearing capacity of the bar after buckling can be fully utilized; and the hot-rolled steel does not allow local buckling of the section.

2. The causes of residual stresses in hot-rolled and cold-rolled steels are different, so the distribution on the cross-section is also very different. The residual stress distribution on the section of the cold-formed thin-walled steel is curved, while the residual stress distribution on the section of the hot-striped steel or welded steel is a film type.

3. The free torsional stiffness of hot-rolled steel is higher than that of cold-rolled steel, so the torsional properties of hot-rolled steel are better than those of cold-rolled steel.

上一篇:Structural rib spiral pipe

下一篇:没有了